- Home

- Faq

- Sales Questions

- Headset Options

Headset Options

SELECT |

Upper & Lower Headset Bearing Or Headset Cup By Head Tube Size |

| Fully-Integrated ( IS ) | |

| 41 / 42 / 47 / 52 / 62 | |

| Top & bottom inner diameter, in mm |

SELECT |

Upper Headset Top Cover |

.png) |

.png) |

.png) |

.png) |

| Concave (CAV) | Conical (CON) | Convex (VEX | EVEN(EVE) |

SELECT |

Bearing Options |

| Type / Material | Friction Performance | Sealing Effectiveness | Corrosion Resistance | Cost |

Loose Ball Loose Ball |

|

|

|

|

Semi Cartridge Semi Cartridge |

|

|

|

|

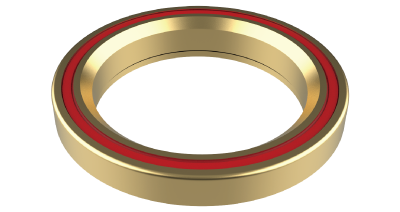

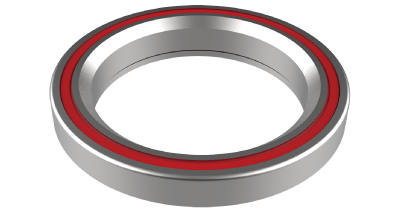

.png) Double Seal ACB / SUJ |

|

|

|

|

Double Seal Double SealACB / SUJ+Tib |

|

|

|

|

Double Seal Double SealACB / SS |

|

|

|

|

SELECT |

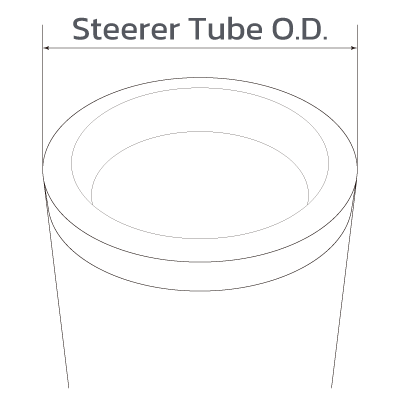

Crown Race by Steerer Tube Size |

|

Steerer Tube O.D. |

| 27mm ( 1” ) | |

| 30mm ( 1 1/8’’ ) | |

| 33mm ( 1 1/4’’ ) | |

| 40mm ( 1 1/2’’ ) |

Finish Options

Alloy finish

The standard finish for alloy top covers and top caps is anodized black. This gives it a slightly shiny look that’s easy to clean. There are also a wide range of options available including BB Matte Black, anodized colors and painted.

Carbon finish

The standard finish for carbon top covers and top caps is UD gloss which is easy to clean and highlights the fact that it is carbon. GW offers the option of a matte finish on carbon parts. The top cover can also be painted in any color so it can perfectly match a frame or component or add some contrast to a bike.

Logos

GW headsets come standard without logos, but we can customize an alloy top covers with laser logos in white or in black. If you require a very unique design, we offer the option of decals on both alloy and carbon top covers.

If you have technical questions, would like to know more about customizing the headset or can’t find a specification you require, please get in touch with your sales contact or email the technical desk at tech@gw-mfg.com.